The Challenge

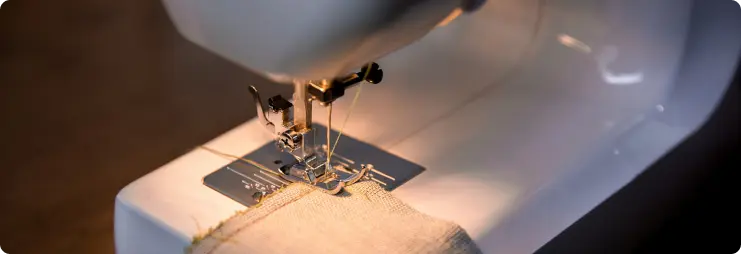

Textile machines with legacy PLCs had frequent unexpected breakdowns

No real-time visibility into critical PLC parameters across production lines

Manual monitoring limited to twice per shift inspections

Reactive maintenance approach causing expensive emergency repairs

Improper production planning due to lack of real-time machine performance data

Our Solution

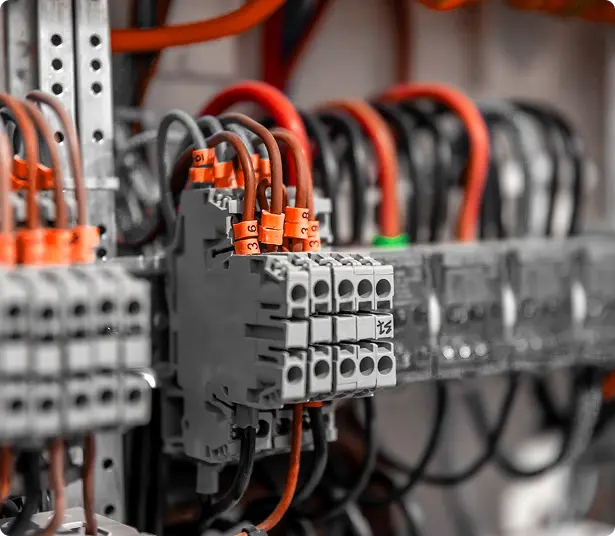

Direct PLC integration with existing legacy devices without production disruption

Secure MQTT and OPC-UA protocols for cloud data/internal server transmission

Custom IoT app development for real-time monitoring dashboards, for industrial engineers to monitor the activities and make strategic decisions

AI service provider capabilities for predictive maintenance algorithms tailored to specific devices and environments for accurate results

AI-IoT Integration Highlights

Real-Time PLC Monitoring with AI-Powered Predictive Maintenance for Complete Operational Excellence

Business Impact

Results that Matter

-

Reduced Downtime by 30%

From 40 hours/month to 12 hours/month

-

Extended Machine Life by 30%

Proactive maintenance based on PLC data

-

99% System Uptime

Reliable legacy device integration performance

Why Nuventure

Legacy Device Integration Expertise

Seamless connection to existing textile PLCs

Complete IoT-AI Service Provider

From IoT app development to predictive analytics

Smart Factory Solutions

End-to-end transformation capabilities

Local Indian Support

A team with textile industry knowledge

Great Ideas Deserve the Right Team!

At Nuventure’s AI Innovation Lab, we collaborate with you - securely and professionally - to turn your vision into reality. Let’s talk!